AI has the ability to transform the Oil & Gas industry by introducing unprecedented efficiencies, enhancing exploration, optimizing production, and mitigating safety risks.

Over the past few decades, the industry has invested significantly in instrumentation, industrial automation, and SCADA for process control and safety. While these systems excel at what they were designed for, they lack the predictive capabilities and other intelligent capabilities of AI like object and anomaly detection.

1/7

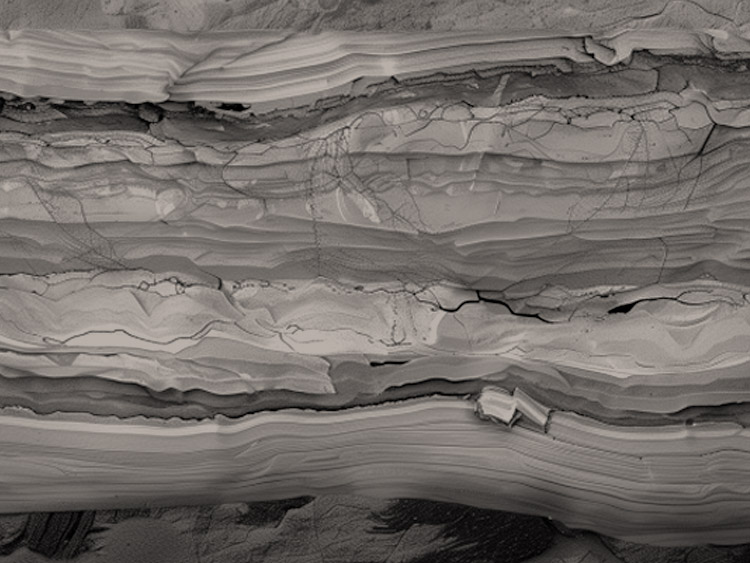

Exploration and Reservoir Characterization

2/7

Drilling and Completion Optimization

3/7

Production Optimization

4/7

Equipment Maintenance and Reliability

5/7

Supply Chain and Logistics Optimization

6/7

Health, Safety, and Environmental Protection

7/7

Energy Efficiency and Emissions Reduction

01

The Global AI in Oil and Gas Market size is expected to grow from USD 2.67 billion in 2023 to USD 4.63 billion by 2028, at a CAGR of 11.68% during the forecast period.

02

In 2021, the rate of job-related injuries and illnesses for the oil and gas industry in the United States was 1.6 per 100 workers. This figure has been consistently decreasing during the period in consideration, aside from the most recent figure. Technology has played a major role in this reduction, and AI has the potential to decrease it even further.

03

High production or machine downtime is a growing scourge in the global oil and gas industry. An Aberdeen research found that the cost of unplanned downtimes worked out to around $260,000 every hour in 2016. When focusing on the causes of this downtime, a recent study conducted by Vanson Bourne for Service Max found that human error was the leading cause at 23%, while 70% of the surveyed companies had a complete lack of knowledge about their equipment condition.