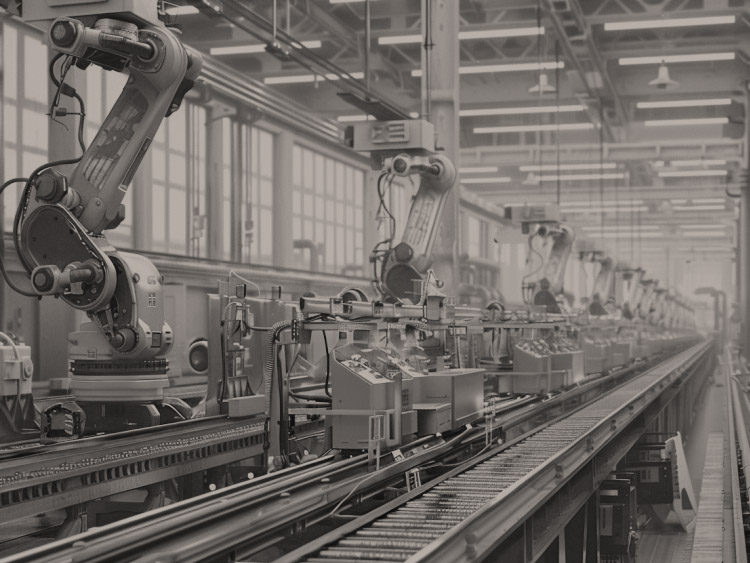

In the ever-evolving landscape of the manufacturing industry, the integration of Artificial Intelligence (AI) stands as a pivotal turning point, heralding an era of unprecedented efficiency, innovation, and competitiveness. AI, with its vast array of capabilities, is not just an add-on but a fundamental paradigm shift, reshaping how manufacturing operates from the drawing board to the final product – providing increased productivity, quality, sustainability, and customization.

1/7

Predictive Maintenance

2/7

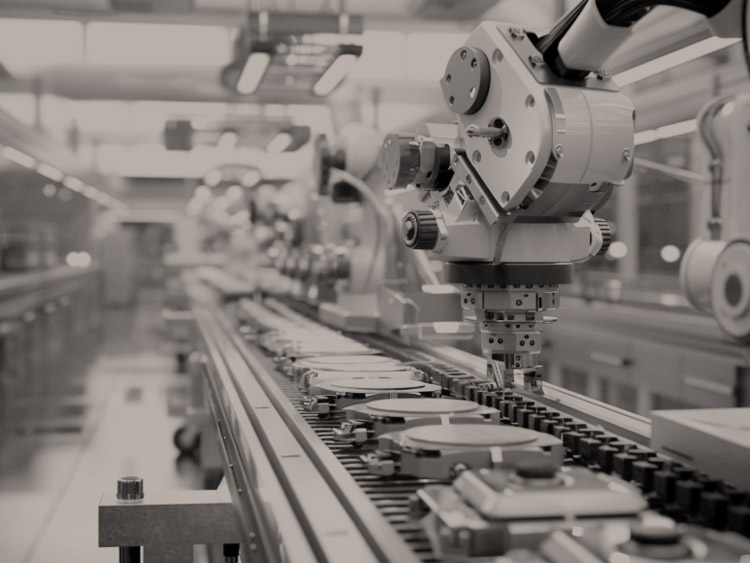

Quality Control / Defect Detection

3/7

Supply Chain Optimization

4/7

Smart Manufacturing

5/7

Energy Management

6/7

Worker Safety

7/7

Process Optimization

01

The global artificial intelligence (AI) in manufacturing market size was reached at USD 3.8 billion in 2022 and it is expected to hit around USD 68.36 billion by 2032, growing at a CAGR of 33.5% over the forecast period 2023 to 2032.

02

In the private manufacturing industry during 2020, there were 373,300 total recordable cases (TRC) of nonfatal injuries and illnesses. Of those, 135,900 had days away from work (DAFW), 108,800 had days of job transfer or restriction (DJTR), and 128,700 had other recordable cases (ORC). The total recordable case incidence rate per 100 full-time equivalent (FTE) workers was 3.1.